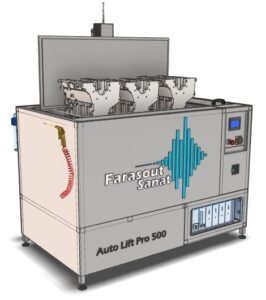

Degassing process in Kellner ultrasonic devices

The process of degassing or degassing in ultrasonic cleaning involves removing trapped gases from the cleaning liquid or solution inside the tank, before starting the actual cleaning operation. This process is especially important in large ultrasonic cleaning tanks and larger systems, as a larger volume of liquid can hold more dissolved gases that may interfere with the effectiveness of the ultrasonic cleaning process.

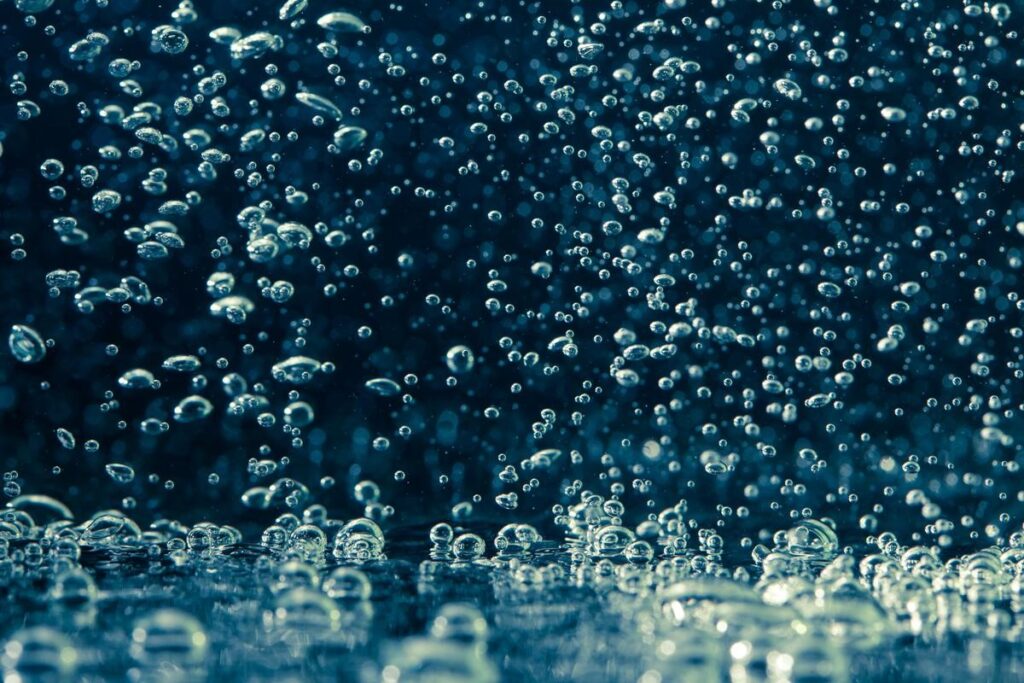

Entrapped gases can reduce the efficiency of cavitation (the formation and collapse of microscopic bubbles). Cavitation is a key process for cleaning operations, as the collapse of bubbles creates small shocks that dislodge dirt, grime, and particles from objects to be cleaned. When gases are present in the liquid, they can disrupt the formation and growth of cavitation bubbles.

The degassing or degassing process is usually done as follows:

-

- Tank filling: The ultrasonic cleaning tank is filled with the cleaning solution or liquid required for the cleaning operation. This solution can be water with washing liquid or a special cleaning solution suitable for cleaning the part.

- Degas Mode: Many modern ultrasonic cleaning units have a “degas” mode, or setting specifically designed to remove trapped gases from the liquid. When this mode is activated, the ultrasonic transducers generate ultrasonic waves at a lower power for a longer period. (from 10 minutes to 60 minutes)

- Gas bubbles rise to the surface of the water: The passage of ultrasonic waves through the liquid causes the trapped gases to come out of the solution, then the air bubbles rise to the surface of the liquid and combine with air, which means removing the gases from the liquid.

- Dispersion of gas bubbles: During the degassing process, trapped gases are gradually released and the liquid is saturated with less dissolved gases. This prepares the liquid for the cleaning operation to ensure that cavitation bubbles are formed and collapse effectively.

- Start cleaning: After the degassing process is complete, the ultrasonic cleaning unit can be switched to its normal cleaning mode, where higher-power ultrasonic waves are used to create stronger cavitation bubbles to aid in the cleaning process.

It is important to remember that the degassing process does not require precise control and several factors must be considered to determine the exact degassing time for your particular setup. If you are working with special cleaning solutions or have specific cleaning needs, consulting with the manufacturer or an expert in the field of ultrasonic cleaning can provide helpful guidance tailored to your specific situation.