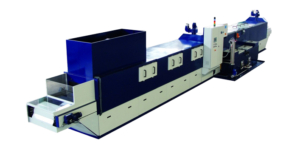

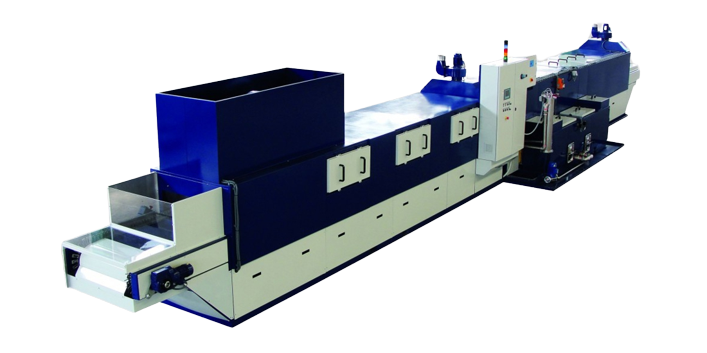

Water-based degreasing and washing machines (LOGICA BLUE)

Washing based on the rotation or vibration of the basket on the horizontal axis

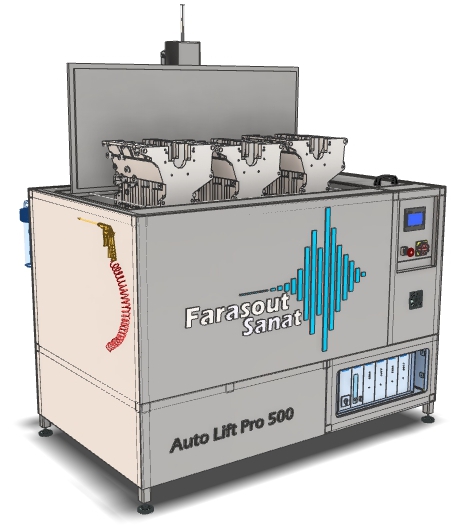

High accuracy of washing by spraying water and solution to the piece or using the ultrasonic washing system

Equipped with Siemens PLC with the possibility of choosing a washing program

Compliant with the highest standard UNI-LS04406 for parts of aluminum, bronze, titanium and various materials.

Drying system based on vacuum or hot air drying or combination of all methods

Washing steps:

- Full or partial immersion

spray - Immersion rinse

- Compressed air blower

- Compressed air blowing by blade nozzles

- Dry with hot air or under vacuum

Washing steps in Logical blue systems:

Logical blue systems, with the possibility of designing and building with 1 to 5 tanks, provide the possibility of doing all the washing steps.

The first phase of washing the part surface:

After being placed in a special basket, the parts are then directed into the machine, the first pump has the task of spraying water and detergent solution with a temperature of about 60 to 70 degrees Celsius through the nozzles into the washing chamber. At the end of this process, the water and solution return to its storage tank after separating the impurities.

The second phase of rinsing

The second pump sends solvent-free water, which has a temperature of about 60 degrees, to the washing tank through the nozzles, and at the end of the used water, it returns to the tank after separating the pollution.

The third phase – drying:

First, the air in the washing tank is transferred to the heating section, and after creating a suitable temperature, it is pumped back into the washing tank.

The third phase of evacuation:

When the door of the machine is opened, a suction fan is responsible for directing the air inside the washing tank to the outlet in order to prevent steam from interfering with the emptying operation.