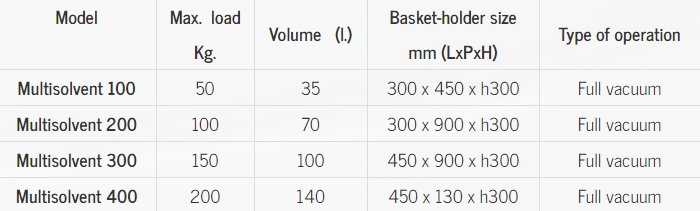

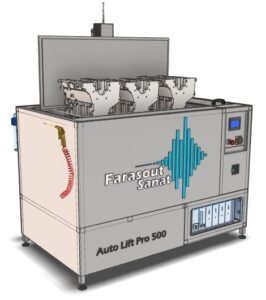

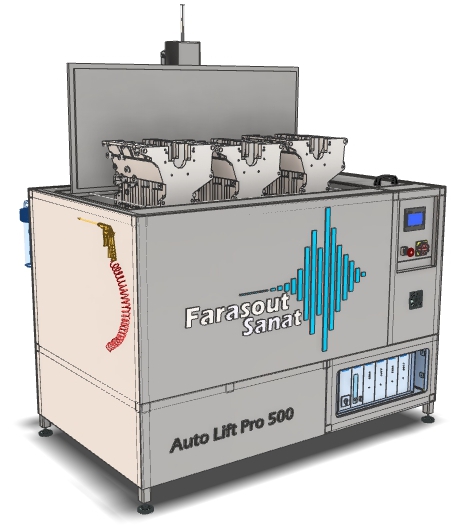

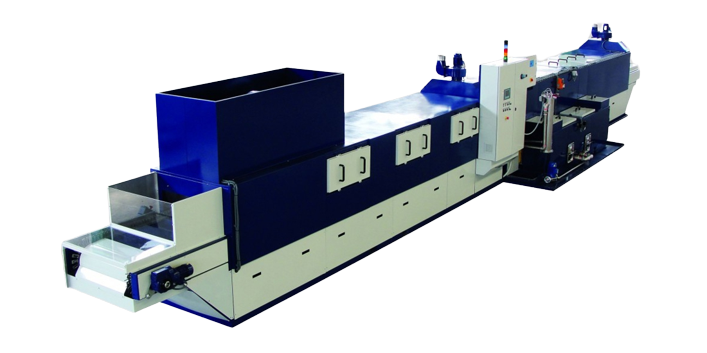

Degreasing machines based on hydrocarbon solvent and alcohol model (MULTISOLVENT)

Salted parts machines are suitable for small parts with minimal consumption of solvent

The best system for washing small parts and drying them under a vacuum with a pressure of less than 1 millibar

Consuming less than 2 grams of solvent per washing cycle

Super easy maintenance and washing

Ability to work continuously for 10 hours a day

The possibility of designing an automatic filling and emptying system

Suitable for :

- Precision machine parts such as:

- Components of mechanical and hydraulic systems

- Valve, rod and gear

- Specially designed parts

- Implementation of printing systems and sensitive printers

- Functional features:

- Complete process in complete vacuum conditions:

- Washing chamber – Tanks – Distillation device – Condenser and pipes are all made of stainless steel

- Rotary vacuum pump

- Baskets with lids to prevent parts from falling

- Solvent storage tank

- Steam condensing system at 30 degrees

- Electric steam generator

- High efficiency distillation unit

- Primary filtration system controlled by PLC

- Ultra filtration

- Siemens brand PLC with HMI display

- Ultrasonic transducers to increase the quality of washing