Cleaning contaminated parts has often been a big challenge for various industries, including oil and gas and petrochemical industries. Despite all the efforts made in the design of processes and hardware to minimize deposits in these equipments, always due to the complex internal surfaces of parts such as air charge coolers; Heat Exchangers; filters, and… cleaning and restoring them to optimal working efficiency; It is a very complex operation.

Currently, the method of reviving hand parts is chemical washing or using high-pressure water spray; While in the chemical washing method, there is always a need for an accurate understanding of the properties of sediments, and at the end of the process, the complex surfaces of the parts may not be completely cleaned; Another inefficient method is high-pressure water spraying, which, in addition to not providing a guarantee for 100% restoration of parts, requires a lot of time and manpower and uses a lot of water.

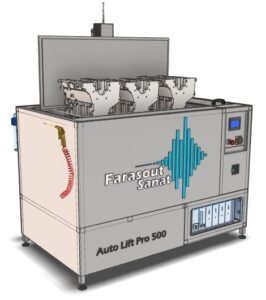

The opposite of these traditional and ineffective washing methods is using the power of ultrasonic waves in washing

It is a complex industrial part.

In this washing method, the most important advantage is the penetration of energy and the cleaning of inaccessible points inside the parts.

The working method of ultrasonic systems is that parts are immersed in tanks filled with water and cleaning materials, and after setting the washing time and temperature by the operator, the washing operation is performed without human intervention. In such a way that right from the moment the parts are placed in the ultrasonic bath, a large amount of contamination is quickly removed from the part.