Ultrasonic cleaners can be effective in removing rust from metal parts, especially if the rust is not deeply embedded.

The ultrasonic cleaning process involves the use of high-frequency sound waves to create microscopic bubbles in the cleaning solution. The collapse of these bubbles creates a tiny shock that can destroy various pollutants, including rust.

Here are some general steps you can follow when using ultrasonic cleaners for rust:

Choose the right cleaning solution:

Use an appropriate cleaning solution that is compatible with the metal parts you are cleaning and the type of rust you have. Mild acids such as vinegar or a specialized anti-rust can be effective.

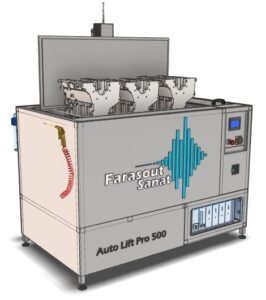

Prepare the ultrasonic device:

Fill the tank of the ultrasonic cleaner with the recommended cleaning solution.

If possible, disassemble the parts:

If possible, break the object into smaller pieces.

It is often helpful to do this to ensure all surfaces are exposed to the cleaning solution.

Place the object in the ultrasonic device:

Immerse the rusted object in the cleaning solution in the ultrasonic device.

Turn on the ultrasonic cleaner:

Turn on the ultrasonic cleaner and let it work for a suitable time. The duration depends on factors such as the severity of the rust and the strength of the ultrasonic cleaner.

Check and repeat the operation if necessary:

After the cleaning cycle, inspect the object to see if the rust has been sufficiently removed. If necessary, you may need to repeat the process.

It is important to note that although ultrasonic cleaners can be effective in removing surface rust and corrosion, always put safety first and take proper precautions when using chemicals and equipment to remove rust. comply If you are dealing with valuable or delicate items, or if the rust is extensive, you may need to consult with the company’s ultrasonic specialists or show it to us for evaluation.