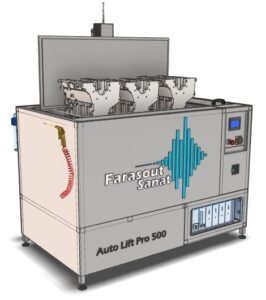

Customized 2000 liter ultrasonic washing line

This washing line is the largest tank equipped with ultrasonic transducers in the country, which was designed and built by the engineering team of Farsaut Sanat Company. The complete work process includes three steps: pre-washing, ultrasonic washing, rinsing (according to the customer’s order), and each step is done automatically.

Pre-wash tub:

- Parts pre-washing tub with dimensions 1100*1200*1700 (L*W*D mm) made of 316L stainless steel with steel coating and heat insulation

- Equipped with a linear spraying system to clean floating pollution on the surface

- Equipped with overflow system for flow

- It has a continuous level gauge

- It has an electric heating system

- Equipped with intelligent tank filling system

- It has a bubbling system in the tank to complete the pre-washing process

Ultrasonic washing tub:

- Dimensions 1100*1200*1700 (L*W*D mm) made of 316L stainless steel with steel coating and heat and sound insulation.

- Equipped with 6 ultrasonic transducer racks, 1500 watts made by BANDELIN, Germany

- 9 kW ultrasonic generator made by BANDELIN company in Germany with the ability to adjust the output power of ultrasonic

- Connected to the PLC system for monitoring and intelligent control of the line

- It has a dry run protection system

- Equipped with an over temperature protection system

- Possibility of separate programming of each of the converters through the software

- It has an ultrasonic time adjustment remote control

- Equipped with a linear spraying system to clean floating pollution on the surface

- Equipped with overflow system for flow

- It has a continuous level gauge

- It has an electric heating system

- Equipped with an intelligent tank-filling system

Rinsing tub:

- Dimensions 1100*1200*1700 (L*W*D mm) made of 316L stainless steel with steel coating

- Equipped with automatic hot water spraying system

Balance tanks:

Intelligent piping and control system for filling the tanks and transferring the solution inside the tubs to the balance tanks

Transport system:

- Two axle crane

- Soft start system for precise control of basket movement

- Steel basket for carrying parts

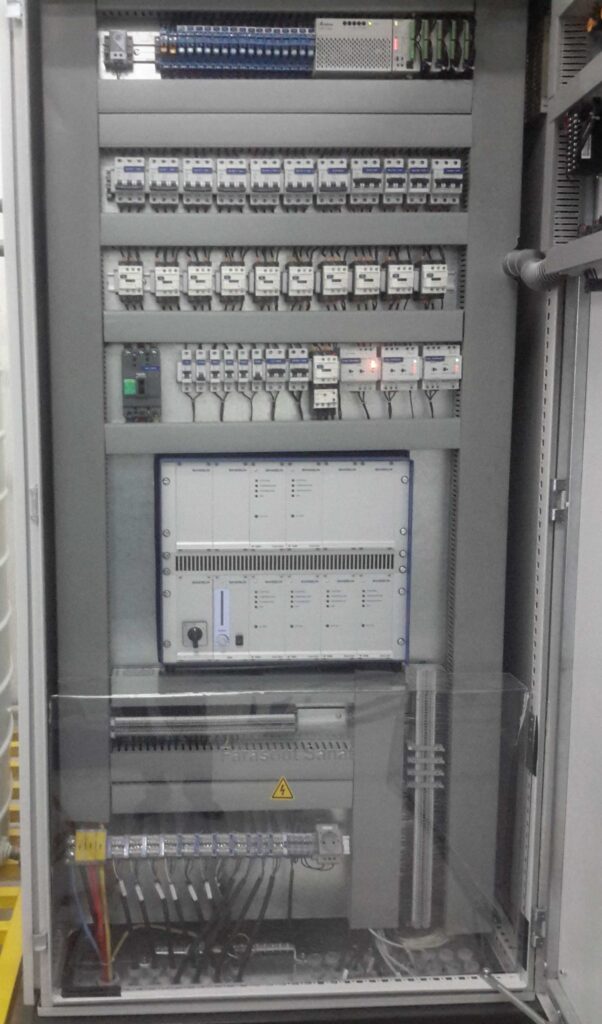

Dashboard:

Including electrical and electronic equipment, to control and feed system tools and equipment:

- plc controller system

- Ability to choose automatic and manual

- washing mode

- Ultrasonic generator

- Power circuits

- Temperature monitoring

- Signal lights

An example of parts washed in this ultrasonic system